Slickline Services

SPRINT Oil & Gas Services offers intervention services conveyed on slickline to address the requirements of wells during the construction and production stages. SPRINT provides slickline services at both rig and rig-less locations for some of the largest and most active operators around the Middle East and Asia.

SPRINT slickline units are compact in design and are engineered in our "Equipment Development and Re-Furbishing Center (EDC)" to suit both onshore and offshore locations.

Slickline services are run by highly trained professionals with over 20 years of experience in slickline services. SPRINT training platform “SPRINT Training and E-Learning Platform” trains the slickline professionals with desired knowledge and competencies to perform varying natures of operations at the most challenging locations.

Besides standalone operations, SPRINT’s slickline services complement its well-intervention services, thereby, improving the value delivered to end users. Slickline services are intensively used along with coiled tubing services to reduce operating times, increase throughput time, and increase the value of overall operation.

Slickline services also present a key advantage in offering integrated services to our customers, with ONE-STOP-SOLUTION for many applications, including but not limited to Plug and Abandonment operations where the complete scope of work can be handled by SPRINT using a combination of its intervention and pressure pumping services.

Slickline Equipment

|

SPRINT provides a wide range of slickline units with capacities ranging from 0.092” to 0.125” and above, suitable for up to 30,000 ft depth. SPRINT slickline units are capable to achieve line speed of 463m/min and maximum pull weight of 3,838 kg. SPRINT slickline equipment is designed to work in both sweat and sour environments with desired pressure ratings of 5k psi, 10k psi, and 15k psi. Also, it is compatible to perform services at temperatures as low as -4° F and as high as 400° F. Slickline units are available for Zone-I and Zone-II requirements with desired pressure ratings and pressure control equipment (PCE). The PCE available in SPRINT resources varies from 3” to 7”, as required, based on the planned application of the intervention. Each slickline unit arrangement allows efficient rig-up and rig-down of the equipment with an excellent field of vision. |

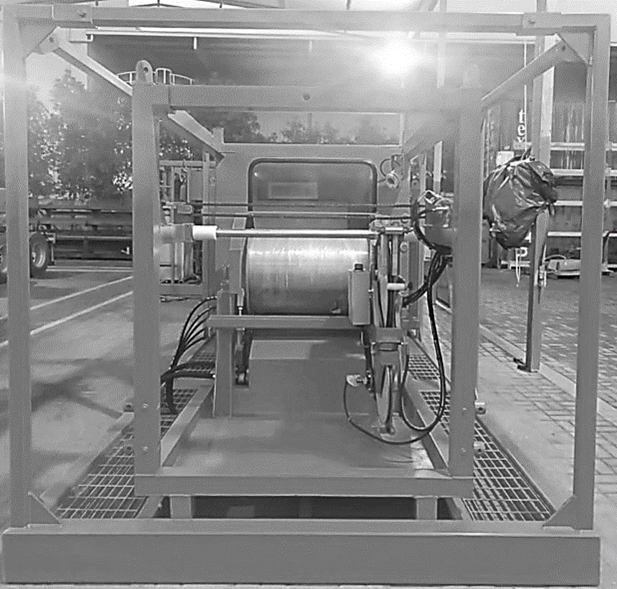

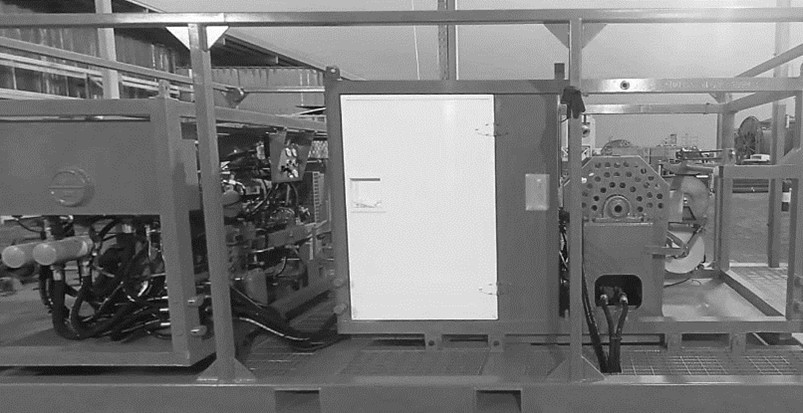

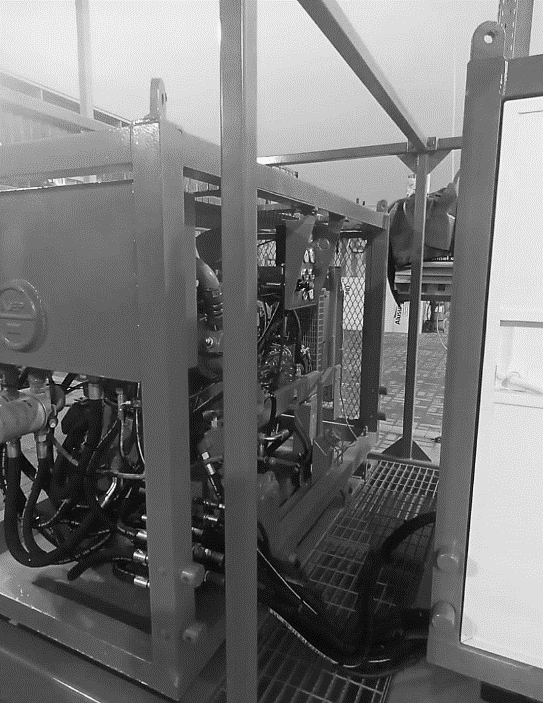

Slickline Unit

|

SPRINT’s slickline units are either skid or trailer mounted and designed for both land and offshore operations. Slickline units are comprised of five main elements: 1. Power Pack Module 2. Operator Cabin/Drum Winch Module 1. Blow Out Preventor 2. Lubricators 3. Stuffing Box The power pack module and cabin module are fitted in one frame, separatable though, with a full protective crash frame allowing safe and easy transfer and transportation both inland and offshore. Whereas PCE is stored and moved in a dedicated full-protection crash frame for the same reasons. In addition to the five elements above, slickline units are also equipped with a tool basket containing all the necessary downhole tools required primarily for the intended operation as well as for any contingent requirement. The Winch system, an integral part of the unit, is chain driven and contains a fail-safe sprint return brake. Moreover, the depth and tension system MP 16 II used in SPRINT's units is a lightweight measuring head with an integral load cell, that increases the precision of depth. |

Slickline Tools

SPRINT’s inventory of slickline tools includes but is not limited to the below-listed tools in different sizes (1-7/8” and above):

Features and Benefits

The key features and benefits of SPRINT slickline units are: