Stimulation and High Pressure Pumping Services

Sprint Oil & Gas Services offers various production enhancement solutions through a wide range of well stimulation techniques and products. Sprint’s goal is to provide cost effective and efficient solutions that increase well production. These innovative solutions are supported by industry-leading products and technologies, however, each treatment is carefully customized to suit each specific application.

Sprint’s solutions cover various systems and products for treating limestone, sandstone and shale formations. From matrix stimulation to well fracturing, we provide a full range of systems and fluids specifically designed in our District and Regional Labs to suit defined well conditions and formation lithology.

Sprint’s additives and products accommodate bottom hole temperatures from 100-400°F. Each system is thoroughly tested in the laboratory prior to job execution to ensure treatment compatibility and damage free fluids.

Every acidizing job is carried out as per Sprint operating standards by highly trained and experienced personnel.

Sprint has a wide range of acid and solvent systems, each is designed to provide optimal treatment for specific well impairment. Our main Stimulation systems are:

- SRA silt and particle removal acid

- ORA organic retarded acid

- NDA diverting acid system

- NDAS nondamaging diverting acid system

- AHCL alcoholic HCL aci

- AHF alcoholic HF acid

- DPGA deep penetrating gelled acid

- NDP non damaging pill

- CarboCLEAN and SulfCLEAN scale clean out systems

- Organic solvent

- NDF non damaging fracturing fluid

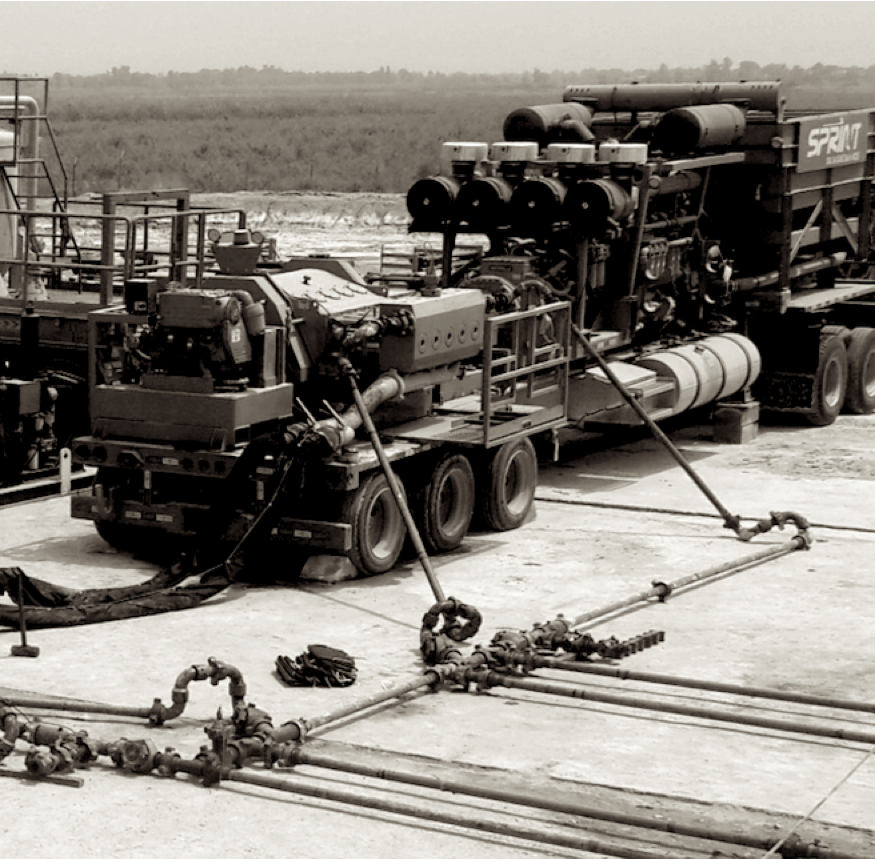

Stimulation Equipment

Sprint’s large horsepower capability delivers Stimulations in high pressure zones at high injection rates. This large horsepower helps efficient fluid diversion during matrix stimulation treatments as well as supports the pumping of various treatments at higher than frac gradients (hydraulic fracturing).

Sprint’s pumping fleet totals more than 20,000 HHP, with individual units delivering 600-2,500 HHP. Our fleet is capable of operating pressures of up to 20,000 psi based on selected fluid-end sizes.

Sprint’s experienced personnel and wellbore simulators for coiled tubing, stimulation and fracturing allow us to recommend the most appropriate treatment design for our clients.

Here is additional information about Sprint’s Stimulation equipment:

- WB2600 Double Pump Unit

- SFP2500 Fracturing Pumper

- 5,000-20,000 Gallons Mixing Tanks

- Fracturing Tank SFT 300-500 BBL

- Centrifugal Pump Skid

- Iron Basket

- Batch Mixer RMX100

- Martin Decker Chart Recorder

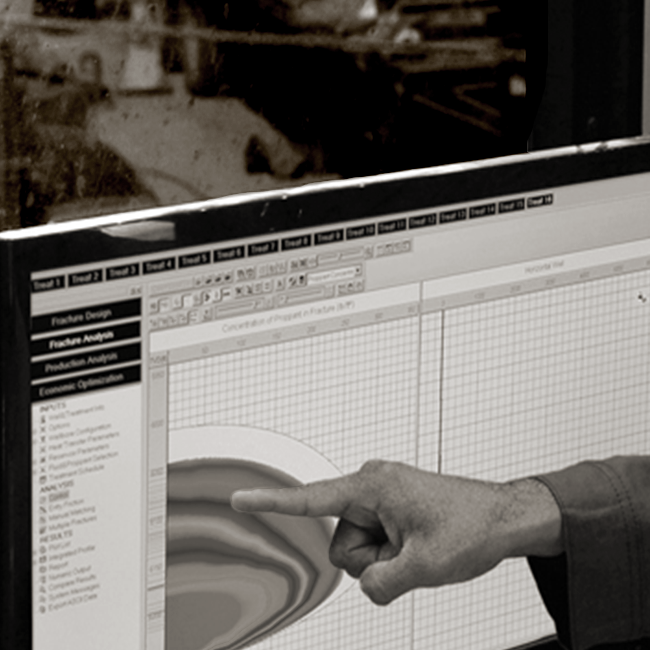

Job Design and Evaluation Software

Sprint Oil & Gas Service uses industry leading software, STIMPRO and FRACPRO, to design and evaluate the effectiveness of matrix and fracturing treatments. With the aim of maximizing the productivity and net present value for our customers, both STIMPRO and FRACPRO carefully recommends the right combination of fluid types and volumes, chemical blends and their amounts, pressures and rates to remove skins in a cost effective manner.

STIMPROSTIMPRO’s matrix acidizing analysis software enables the design, simulation and analysis of acid injection treatments below the fracture initiation pressure. The Windows based design software is effective in modelling both carbonate and sandstone formations. With carbonates, the program calculates the mass dissolution of formation/damage based on formation and acid treatment types. The unique features and powerful capabilities of the STIMPRO system allows for quick design, analysis and optimization of acid jobs. The system facilitates modifications during job execution and assists in performing a complete post job analysis. This increases production and improves the economics for acidizing treatments. |

FRACPROFRACPRO effectively models any type of pressure stimulation (fracturing) job such as limited entry wells, multiple perforated intervals and horizontal well fracturing. It can model fracture growth in any formation — carbonate, sandstone and even coal. FRACPRO allows understanding of proppant placement, conductivity improvements and Image fracture dimensions. The software has the capability to incorporate the effects of proppant damage due to crushing, embedment, stress cycling, and nonDarcy and multiphase flow. |

Stimulation Products

To see a complete list of our Stimulation Products, please click on the link below:

Data Acquisition Systems

Sprint uses leading edge design software to predict coiled tubing string performance and fluid behavior at various downhole well conditions. The work history and integrity of each coiled tubing work string is continuously monitored and updated using an electronic data acquisition system coupled with real time modeling and fatigue software.

ORIONOrion is a data acquisition system for pumping services such as Cementing, Stimulation, Nitrogen, Fracturing and Gravel Packing. It is typically used to record, monitor, display and report fluid densities, flow rates, circulation pressures, wellhead pressures, Nitrogen rates and cumulative volumes. OrionNET software acquires and stores important field job data and displays it in real time. It utilizes the Orion viewer to display real time data and Orion report to create customized reports to meet specific reporting needs. |

REAM HMIThe REAM HMI (Real time Electronic Acquisition & Monitoring with Human Machine Interface) is Sprint's data acquisition system of choice that reads data from the different electronic sensors fitted to the coiled tubing unit and displays the data on an 8.4” TFT touch screen. This screen acts as both an input and an output device. The system records the data on solid state compact flash memory and allows for the remote monitoring of the data. The system can also integrate and record auxiliary equipment performance such as the pumping and nitrogen unit operation parameters. |