Coiled Tubing and Thru Tubing Services

|

Sprint Oil & Gas Services offers advanced intervention services conveyed on coiled tubing to improve well and reservoir performance. We provide coiled tubing services for both well intervention and new well completion programs for some of the largest and most active oil and gas producers around the Middle East and Asia. Onshore and offshore, we combine well maintained, state of the art coiled tubing and pumping equipment with expert personnel who have vast experience in coiled tubing operations and associated services such as high pressure pumping, nitrogen pumping, fishing, tubing conveyed perforations (TCP), completion manipulation, stimulation and coiled tubing drilling. The result is consistent, competitive solutions delivered safely and in compliance with environmental regulations. Sprint has an extensive coiled tubing track record covering nitrogen lifting, fill clean out, scale removal and drilling, through tubing fishing and milling, through tubing permanent and retrievable plug setting, velocity string deployment, stimulation for vertical and horizontal wells, coiled tubing logging, perforations and other complex well intervention applications. An experienced technical engineering team supports the coiled tubing operations starting from candidate selection, solution review with clients, and job simulation to plan, execute and evaluate every operation. |

Coiled Tubing Equipment

Sprint provides a wide range of coiled tubing units with capacities ranging from 1 1/4" 20K lbs units to 3 1/2" 100K lbs units with a wide coverage of setups to suit various well pressure up to 15,000 psi and temperature requirement up to 400°F. We also maintain capabilities for operations in a wide range of ambient conditions, especially hot weather environments.

Each coiled tubing arrangement allows efficient rig up and rig down of equipment with an excellent field of view.

Coiled tubing setups are available for Zone I and Zone II requirements and for wellhead working pressures of up to 15,000 psi. 10K psi and 15K psi risers and deployment systems allow deployment of long bottom hole assemblies (BHA) under all types of well conditions.

Coiled Tubing Units

Sprint coiled tubing units are either skid or trailer mounted and designed for both land and offshore operations. Coiled tubing units are comprised of five main skids:

Each skid is supplied with a full protective crash frame allowing safe and easy transfer and transportation both inland or offshore. All coiled tubing units are designed to operate in a wide range of ambient conditions, especially hot weather environments.

Data Acquisition Systems

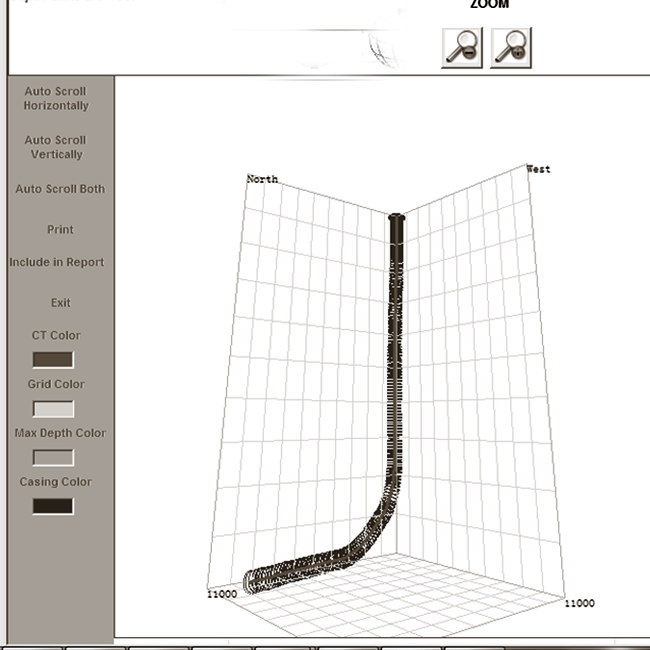

Sprint uses leading edge design software to predict coiled tubing string performance and fluid behavior at various downhole well conditions. The work history and integrity of each coiled tubing work string is continuously monitored and updated using an electronic data acquisition system coupled with real time modeling and fatigue software.

ORIONOrion is a data acquisition system for pumping services such as Cementing, Stimulation, Nitrogen, Fracturing and Gravel Packing. It is typically used to record, monitor, display and report fluid densities, flow rates, circulation pressures, wellhead pressures, Nitrogen rates and cumulative volumes. OrionNET software acquires and stores important field job data and displays it in real time. It utilizes the Orion viewer to display real time data and Orion report to create customized reports to meet specific reporting needs. |

REAM HMIThe REAM HMI (Real time Electronic Acquisition & Monitoring with Human Machine Interface) is Sprint's data acquisition system of choice that reads data from the different electronic sensors fitted to the coiled tubing unit and displays the data on an 8.4” TFT touch screen. This screen acts as both an input and an output device. The system records the data on solid state compact flash memory and allows for the remote monitoring of the data. The system can also integrate and record auxiliary equipment performance such as the pumping and nitrogen unit operation parameters. |

Design and Modeling Software

Sprint utilizes the TAS/FACT/DART simulator bundle and pipe management software to design and model various coiled tubing operations and track the life of coiled tubing strings. These simulators, when combined with the STIMPRO (Stimulation) simulator, enable Sprint to provide a complete design and post job assessment for all well intervention and well production operations.

TASTAS (Tubing Analysis System) is a computer program designed to perform various calculations and simulations often needed in tubular applications. It is used as a coiled tubing job simulator and is used in designing velocity strings, drill pipe applications, underbalanced drilling, coiled tubing drilling, cementing, and wireline simulations. TAS is an integrated modular program incorporating force and stress analysis, fluid circulation, and unload kill fluids, in addition to numerous quick computations often needed in tubular computations. |

FACTFACT (Fatigue Analysis for Coiled Tubing) is a management tool that is used to maximize the safe use of coiled tubing strings. The fatigue analysis tracks life consumption of individual coiled tubing strings and parts of the strings subject to jobs carried out in wells or in the yard, and shows the life consumption per job. In addition, the module gives the user the option of finding the maximum number of cycles to fatigue failure, with or without internal pressure and subject to user specified geometry of the goose neck and the reel. |

DARTDART (Data Acquisition in Real Time) is a quick set up and data acquisition software with minimum input required from the user. The software is compatible with most known hardware systems. DART will acquire, record on to file, graphically display data versus time and create customized job graphs to meet the specific reporting needs in addition to doing realtime computations. Later additional parameters can be computed within DART and/or external parameters that may be imported from the output of another application (REAM HMI) running in realtime. |