Cementing Services

|

Cementing is one of the most critical operations performed on an oil well. The key objective and aim of Cementing is to ensure complete zonal isolation, aquifer protection, and the structural integrity of the wellbore. Sprint Oil & Gas Services has diversified and proven experiences in cementing oil and gas wells. With thousands of cementing jobs performed to date, we provide a wide range of cement slurries that offer solutions to cementing shallow gas wells, deep high pressure and high temperature wells, wells with large sections of salt or shale, wells with shallow or unconsolidated sections, etc. Sprint also has a broad experience in conducting operations in logistically challenging areas and remote locations around the Middle East, East Africa and South Asia. The outcome of a successful cementing job is critical in preventing the loss of production, controlling interzonal flow and/or flow to surface, reducing water production, optimizing production and improving the confinement of stimulation treatments. We combine our extensive technical and field knowledge with innovative tools, equipment, formulations, and ongoing research and development to offer each client solutions to meet or exceed their requirements. Sprint has successfully designed, developed and delivered solutions to address a variety of challenging conditions. These include high temperature, high pressure, extreme losses, gas zones, salt zones, perforations, annulus channels propagated from small fractures and payzone temporary plugging. Sprint’s cementing, pumping and mixing services are supported by state-of-the-art cementing equipment designed and manufactured to industry standards by Sprint's Manufacturing and Maintenance Centre based in the United Arab Emirates. The Sprint cement pump unit WB2600 and batch mixers (CMX20) provide field-proven dependability and an outstanding job quality. They are specially designed for mixing variety of slurries at a wide range of densities and formulations covering 8-23 ppg. This equipment setup also provides flexibility and precision control systems to handle a variety of cementing services. Sprint’s engineers and operational teams are supported by a group of highly qualified and dedicated researchers and laboratory specialists. Along with the contribution of our Technical Support Centre (TSC), regional lab and operational support district laboratories, we provide our clients with optimized cementing systems such as: |

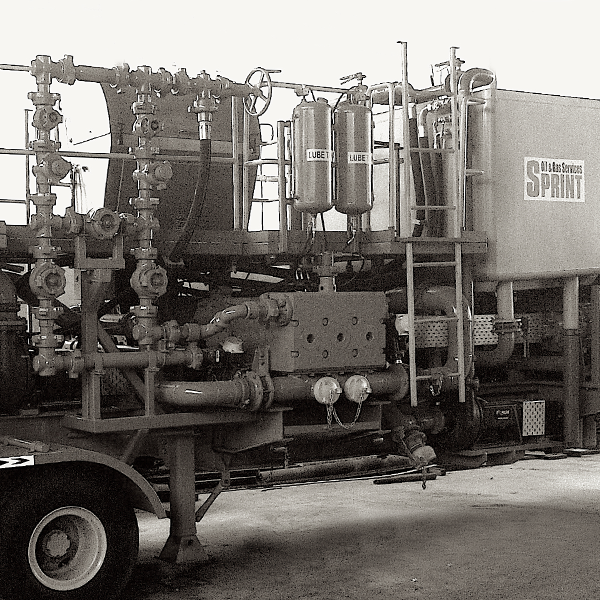

Cementing Equipment

Sprint Oil & Gas Services has state-of-the-art cementing equipment. All cementing equipment is designed to perform sustained operation, manufactured to exacting industry standards and vigorously tested before being mobilized to a client location. Additionally, a maintenance and technical support facility is established in UAE to support our maintenance functions in all our operating countries.

SPRINT cementing pumpers feature climate controlled, Covered operator cabs, mass flow meters (Non Radioactive Densitometer), re-circulating mixers and data acquisition Systems (ORION) for job parameters recording in real time.

The recirculating mixers use a high energy, Tom & Allen mixing system controlled by an automatic mixing & density control system (AMDC) that yields extremely accurate cement densities ranging from 8-23 ppg with a variance of +/0.1 ppg.

Cementing Equipment Specifications:

|

- Bulk Storage Tank - Cement Bulker - Air Compressor - Weigh Batch Blender - Cutting Bottle - Cement Head - Circulating Swage - Fast Latch Coupling (FLC) |

Software Systems

|

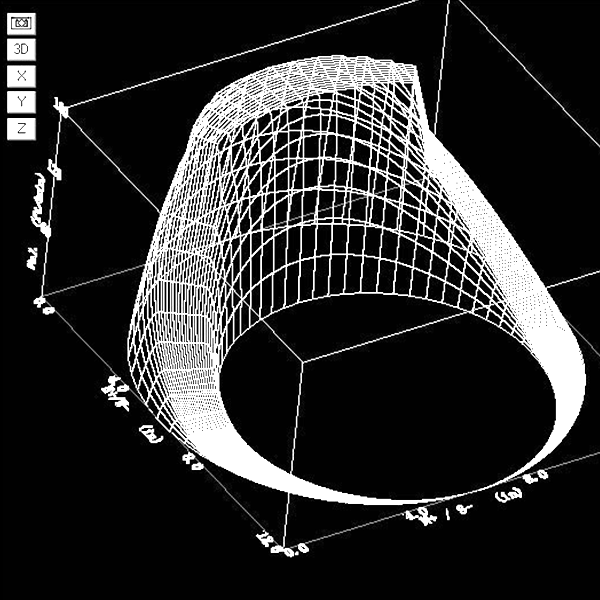

A successful cementing job is one of the most important factors for the productive life of an oil or gas well. Computer modelling has allowed far better understanding of the cement job than was previously possible. Many potential problems can be identified prior to the job and appropriate modifications can be made. Sprint uses advanced simulation software to model and predict optimized centralizer design and placement, cement slurry placement, wellbore properties and temperature changes, and cement sheath integrity. CEMPRO/CEMPRO+The ultimate and most difficult goal of cementing operations is providing zonal isolation by displacing drilling mud with cement slurries. Incomplete mud removal causes a poor cement seal and non-productive time (NPT). To ensure critical zonal isolation with mud removal optimization, Sprint uses job simulators, CEMPRO/CEMPRO+, for the design of optimum mud displacement. CEMPRO utilizes advanced numerical methods to solve momentum and continuity equations on 3D grids and calculates fluid concentration as well as displacement efficiency. It accounts for many factors that can affect the efficiency of displacement jobs, including but not limited to:

CentraDESIGNCasing centralization is one of the key elements to ensure the quality of a cementing job by preventing mud channelling and poor zonal isolation. SPRINT uses CentraDESIGN to select the right type of centralizers and place the ideal number of them at optimum positions on the casing to achieve a good standoff profile. The following parameters can be optimized by CentraDESIGN; |

Cementing Products

To see a complete list of our Cementing Products, please click on the link below: