Nitrogen High Pressure Pumping Services

Sprint Oil & Gas Services provides a comprehensive range of Nitrogen pumping services for onshore and offshore applications. These services are delivered at pressures ranging from atmospheric to 10,000 psi and at rates of up to 180K scf/min for a single pumping package.

Sprint’s fleet of Nitrogen pumpers cover our client’s Nitrogen pumping and purging needs of up to a total of 900K scf/min.

Sprint’s operational team is trained to respond timely and efficiently to our client’s calls and, with the help of the various simulators, set procedures and operating standards, we ensure providing a quality and cost effective solution in various wells, pipelines or plants applications.

Sprint has long standing experiences in Nitrogen services and operations covering thousands of oil well kick offs, Nitrified fluids pumping, foamed acid aplications, foam cementing jobs, leak detection and pressure testing for pipelines, gels and foam pigging for pipelines, gathering centers and processing plants purging, etc.

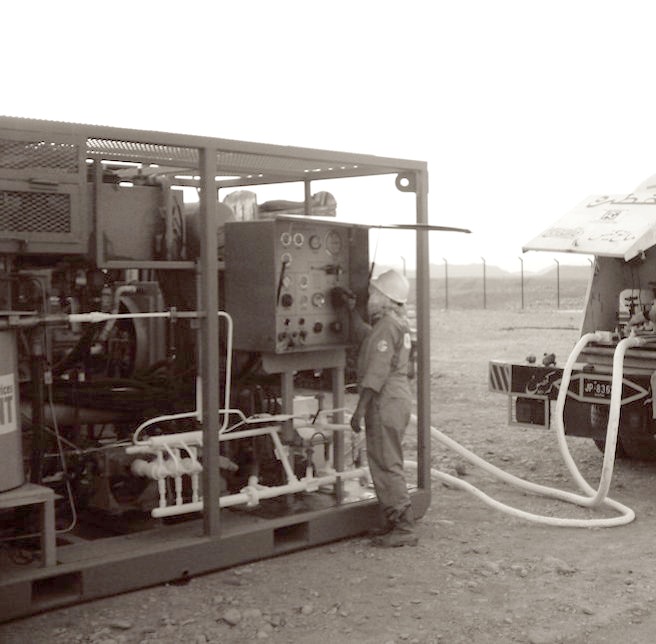

Nitrogen Pumping Equipment

Nitrogen Pumpers

Sprint’s Nitrogen Pumper fleet consists of units with pumping capacities in the 90K-180K scf/min range and pumping pressures capabilities of up to 10,000 psi.

Nitrogen Pumpers are equipped with diesel engines, vaporizers and cryogenic triplex pumps. A variety of fluid-end sizes are available to suit the required pressure and flow rates for each operation.

Units are available on a skid/trailer or on a body load truck which carries a 2,000 or 4,000 gallons (7570 or 15142 litres) nitrogen tank.

Nitrogen Pumping Services

z|

Sprint Oil & Gas Services provides Nitrogen pumping services for several well applications including: Nitrogen LiftingNitrogen lifting is commonly used to enable a well to flow initially or bring a previously flowing well back into production. Nitrogen is used as a means of unloading and under balancing the well to a point where the well flows naturally and driven by its own reservoir pressure. Through a simple calculation, with the known reservoir pressure and weight of the completion fluid in the well, the amount of overbalance can be calculated and the respective minimum depth of lift pinpointed. Sprint TAS, Cempro and Stimpro simulators are used to simulate these calculations. Situations requiring more complex calculations, such as in case of underbalance perforation or foam cementing, can also be quickly and efficiently made using these simulators. Energizing FluidsEnergizing fluids is a technique that allows the pumping of different fluids and acid systems into a well while maintaining the overall hydrostatic pressure of the fluid column in the well bore below reservoir flowing pressure. This enables the well to flow back immediately after the completion of the job without the need to lift the well with coiled tubing and Nitrogen. Energized acid fluids such as Sprint foamed SRA Silt and particle Removal system or foamed DPGA Deep Penetrating Gelled Acid can also help deeper acid penetration and delay its reaction rate. Foam DiversionFoamed base fluids using Nitrogen gas and foaming agents is a well-known technique to create downhole foam pads for diversion purposes. The foam diverter is pumped in staged slugs between main acid stages to divert acid into tighter/non treated zones. Sprint foam diversion service helps improve treatment diversion across the entire pay zone, thus, improving the well stimulation yield while minimizing formation damage when compared to conventional particle diverting pills. Foam CementingFoam cementing is a well-known technique used to design a light weight slurry with densities lower than water, but with outstanding mechanical and dynamic properties. Beside helping for improved slurry placement under low reservoir pressure conditions, it provides set cement with outstanding mechanical properties such as compressive strength and permeability. Sprint foam cement uses industry leading surfactant and slurry stabilizers to develop a stable and ultra-light weight cement slurry. Nitrogen Plant and Pipeline PurgingNitrogen gas is highly effective for pipeline purging, pipelines displacement, plants dehydration purposes and corrosion protection. As Nitrogen is inert, it does not support combustion. Therefore, once a system is purged using Nitrogen, there is no risk of ignition within that system. Nitrogen will also help preserve plants and pipelines and reduce corrosion caused by oxidation making it ideal for protection for prolonged periods of no use. This service also includes: |